The blog posts for this week may be a little empty because I did not do very much woodworking last weekend. It was -15 degrees on Saturday, so my brother and I did a little ice fishing and hammered some of the smallest panfish you’d ever see. It was very fun.

On Thursday I was able to finish the tessellated box, and I’ll attach some pictures. It happened to be a huge struggle and I’m not the most satisfied with the way that it turned out. It looks great, but to get it there was cumbersome and unsmooth specifically regarding the hinges and separating of the lid. I haven’t put finish onto the box yet and that will be the last step. I’m thinking this will be temporary cigar storage until I can make a proper humidor.

The cheap barrel hinges that I used were not the correct ones, and I believe I can do much better on the next box. It would be wise for me to use a specific high quality hinge for every box that I make, then create a jig that makes the installation of that hinge easy and consistent. There are a million different hinges, but Rockler sells nice ones, and there are ones that make the opening and closing of the box more rigid. These hinges give the box a high quality feel when its being opened and closed.

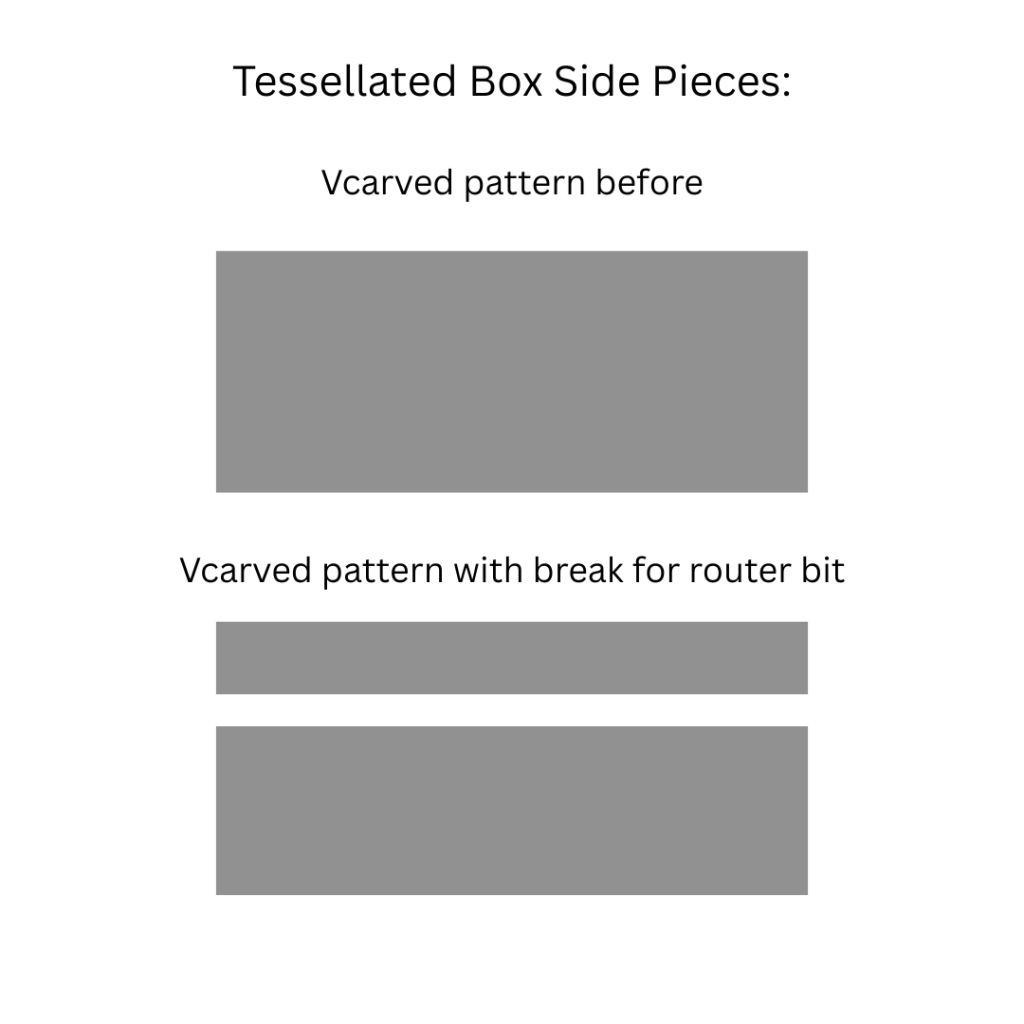

After thinking about the box lid, I’m thinking that I need to separate it at the table saw. Meaning instead of a quarter inch gap for the router, I’ll need to leave an eighth inch gap for the table saw blade. I believe this will deliver the best result, even though cutting the lid out on the table saw seems dangerous, I’m sure it will go smoothly. I could perhaps cut 3/4 of the way through, keeping the lid fastened to the box, then finish the cut with hand saws and planes. That might be the way to go. Seems like a good balance between safe and fast.